Combining domain experts from all over the world with years of industrial experience, we can provide a complete turnkey solution for your factory.

The GLOBAL RETOOL GROUP combines the expertise of the companies SVQ GmbH, WEMA VOGTLAND Technology GmbH, GRG America LLC as well as the brands SIEPMANN, SPICHER, SATEG, LASERplusS, parQing and softQare and encompasses the areas of

Machinery and Plant Engineering Automation & Digitalization Mobility Concepts & Automatic Parking.

A unique combination which makes the company a worldwide renowned turn-key specialist and system integrator.

By establishing a branch office and plant location in the East China city of Yancheng, WEMA VOGTLAND Technology GmbH has taken another step in strengthening its international position and in expanding its portfolio of products and services.

Besides the core competence of retooling & retrofit of machines, the team at the Yancheng location is also focusing on designing & making new machines.

In addition to the well known portfolio of WEMA VOGTLAND, the company is now offering industrial automation integration services to customers in China.

The Global Retool Group’s internationally renowned brand of SIEPMANN represents more than 100 years of tradition and experience in grinding technology. With own patented products SIEPMANN is one of the leading companies in the field of grinding and polishing of cutlery, such as knives or scissors, but also hand tools and machine knives.

The wide range of SPICHER products includes systems for the loading and interlinking of individual manufacturing

machines and cells and even complete automation systems for processing lines and factory halls – from loading of the rough parts to unloading of the finished parts. The comprehensive product portfolio includes gravity conveyors, slat band conveyors, pallet transfer and gantry systems and, last but not least, robots. All of these are used not only for the configuration of new systems, but also for retrofit projects.

For fully automated bin-picking SPICHER supplies robot cells with camera recognition and its patented rough part loading system PILO®.

The SATEG division of SVQ designs and implements automation technology for various industries. Services range from planning and design to assembly and installation, and up to maintenance and service of electrotechnical systems. Customers can rely on SATEG engineers as competent partners for control cabinet build with extensive hardware and software knowledge.

In the consultation stage of the process, we find out your needs, and the best way to help you achieve your production goals.

Together we will evaluate and optimize your current process with the most cost effective methods. Feel free to contact us with any ideas, we are happy to discuss and share.

In the proposal stage of the process, we have assessed your needs and have come up with the solutions we think can best serve you.

Together, we will evaluate a spectrum of solutions to find the ones that fit your needs the most. We are dedicated to providing both tailored and packaged solutions to our clients.

In the discussion stage of the process, we have largely agreed on a few proposed methods of integrating SVQ fixtures with your production line.

Together we will explore details and possibilities of each proposal. It is our aim to help our clients understand all possible requirements and benefits to production so they can make the best informed decision.

In the quote stage of the process, our experts will provide you with a quote we think is required to get the best job done.

Together we can go over any quote concerns, as a well as help conduct any due diligence. We believe in high quality from industry standards after market service.

In the detailed design stage of the process, our experts will blueprint your tailor made fixture we discussed together through the initial stages.

Together we will evaluate and optimize the detail design. Focusing on functionality, operability, safety, as well as durability are the details we find paramount in any design process.

In the review stage of the process, we deep dive into the design to make sure your firm is happy with the design’s functionality and productivity.

Together we will evaluate and optimize the detail design to ensure your tailor made fixture is exactly as you want it to be.

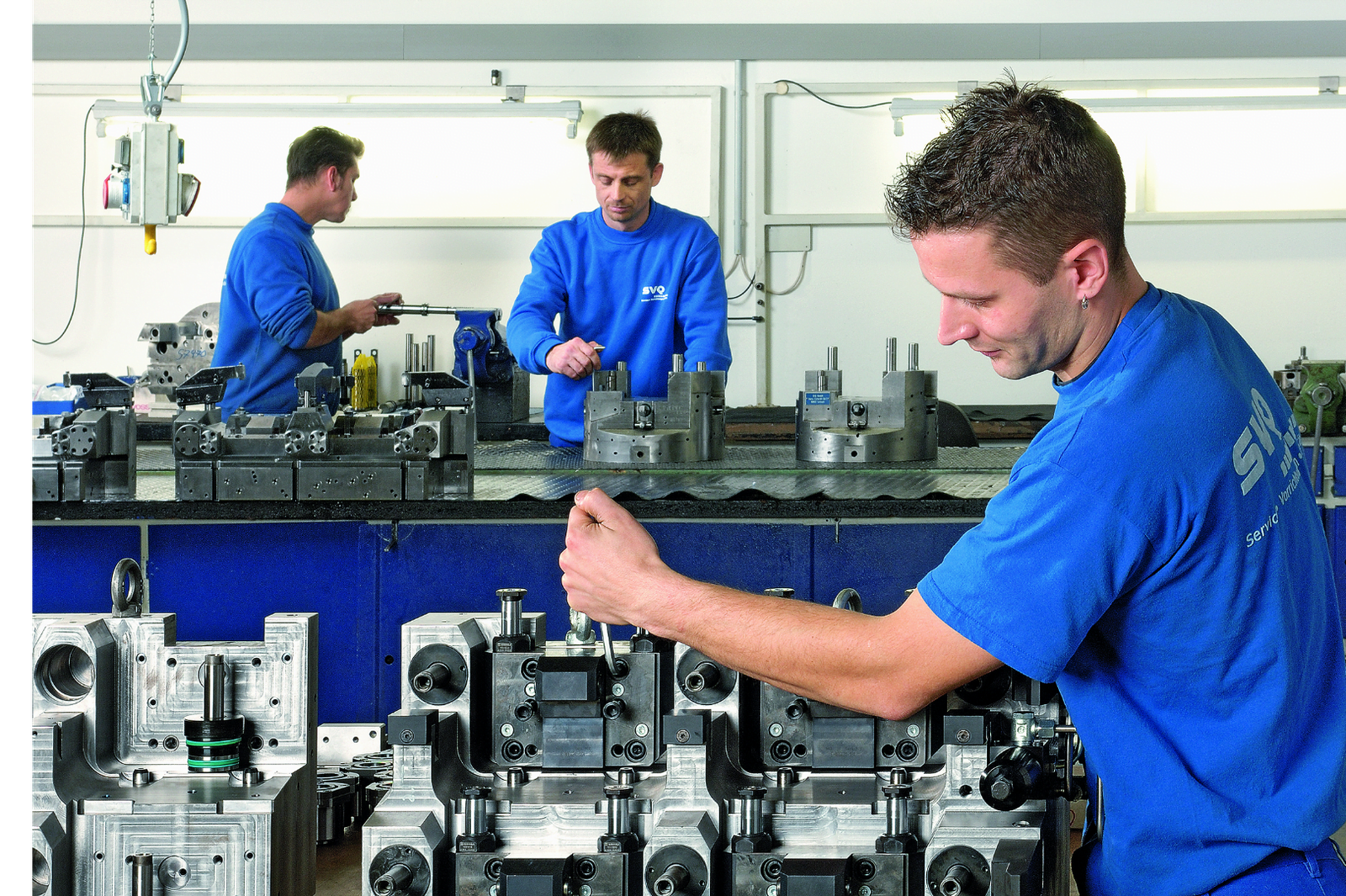

In the production stage of the process, our experts will start crafting your tailored fixture. During this process, you will receive updates on how your piece is developing.

Together we will also go over machine operation procedure, machine know-how, management expertise, as well as quality control systems.

In the assembly stage of the process, we follow the standard operating procedures of our German counterparts in order to complete above standard quality control.

We will evaluate and conduct functionality assessments on your fixture to ensure maximum efficiency and effectiveness.

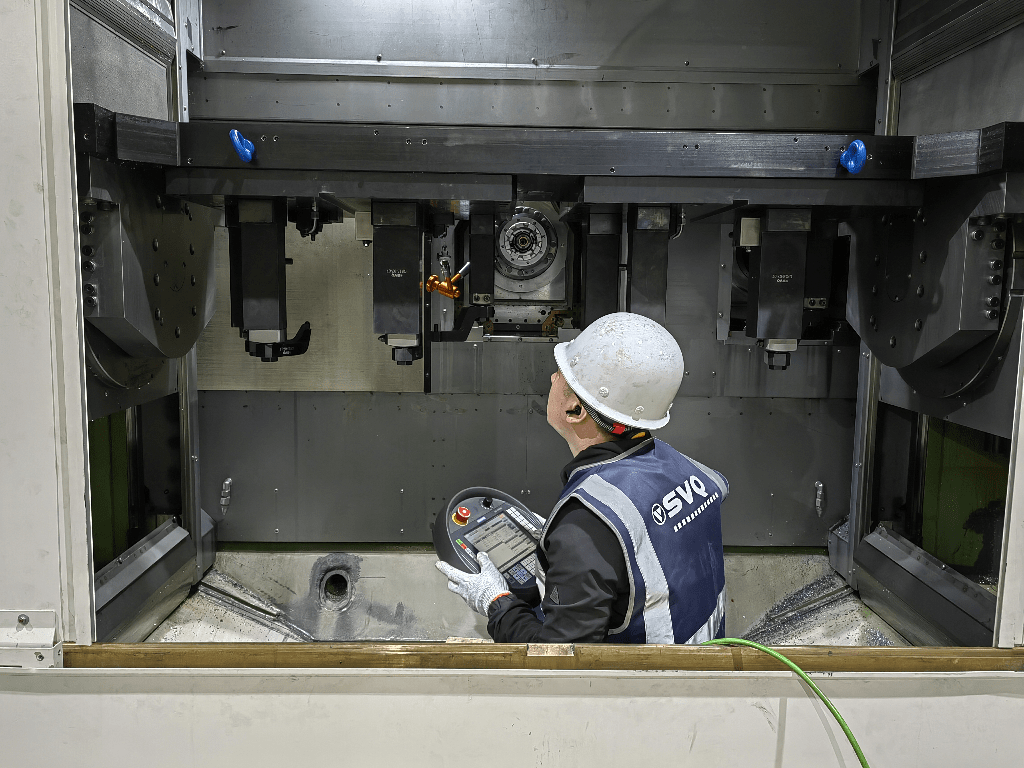

In the installation and optimization stage of the process, our experts will assist your team in installing and running your tailor made fixture.

Together we will evaluate and optimize your new feature to ensure 100% satisfaction. Our highly experienced service teams will be on stand-by 24/7 to make working with us as seamless as possible.

We will evaluate and conduct functionality assessments on your fixture to ensure maximum efficiency and effectiveness.