With the advancement of science and technology, in order to meet the needs of the industry for 70 years, we have provided specialized technical services, and the products of universalities and high efficiency, we have become your reliable high-quality suppliers in various industries.

SVQ Limited the foreign enterprise was jointly established by the German SVQ Group and SCH Group in 2008.

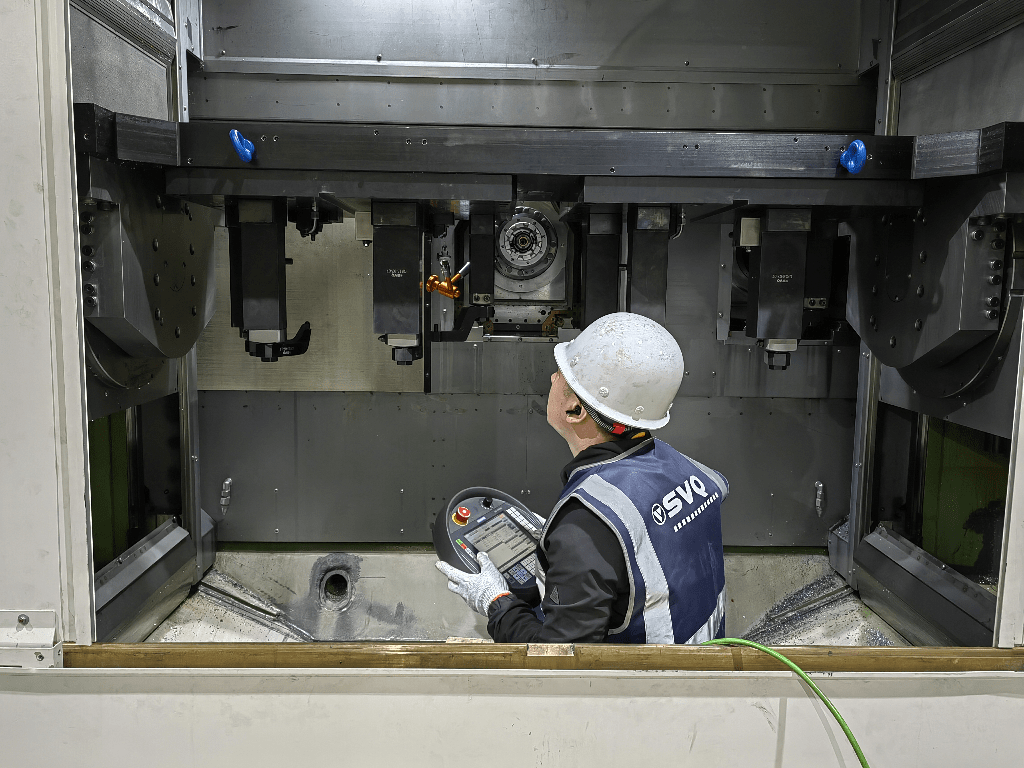

SVQ Limited is a professional supplier of hydraulic clamping fixtures. Factories were equipped with a series of excellent production equipment to master the complete process of all parts manufacturing. Moreover, the company inherits German experience in technology and production to provide high-quality products and services to local customers. With years of experience accumulated, SVQ has achieved remarkable success in various industries, especially in the automotive industry, electric vehicle industry, aerospace industry, machinery industry, new energy industry, electronic industry, etc.

Extensive project experience combined with world-leading technology, we provided customers with more effective, more comprehensive, and reliable products.

In addition to fixtures, the SVQ team is also keen on the Retooling line. Our team can provide the perfect solution for complete line processing. The experienced team perfectly combines and manages all resources. By providing direct service through local engineers, gives customers a cost-effective choice.

Cultivated by years of industrial experience, the SVQ service team has the ability to repair and maintain customers’ on-site auxiliary equipment and provide continuous technical support and optimization services for customers’ production lines.

SCH was founded

Hung Chih Limited Company was founded in Tainan

Brilliant Group International Ltd (Shanghai) was founded in Shanghai

SVQ GmbH was founded

SVQ China CO., Ltd. was founded in Shanghai

To expand business, SVQ China relocate to Kunshan and change into SVQ China Limited

SCH (Sinji industrial park) was founded in Tainan

Fixture after-sales service department was established in Tainan SCH (Sinji industrial park)

Precision production department was established in Tainan SCH (Sinji industrial park)

We aim to provide our clients to with most amount of information before they choose to customize a fixture with us.

Transparent cooperative relationship with customers is our commitment, correct production specification is our insistence, and compliance with international certification is our job.

In the consultation stage of the process, we find out your needs, and the best way to help you achieve your production goals.

Together we will evaluate and optimize your current process with the most cost effective methods. Feel free to contact us with any ideas, we are happy to discuss and share.

In the proposal stage of the process, we have assessed your needs and have come up with the solutions we think can best serve you.

Together, we will evaluate a spectrum of solutions to find the ones that fit your needs the most. We are dedicated to providing both tailored and packaged solutions to our clients.

In the discussion stage of the process, we have largely agreed on a few proposed methods of integrating SVQ fixtures with your production line.

Together we will explore details and possibilities of each proposal. It is our aim to help our clients understand all possible requirements and benefits to production so they can make the best informed decision.

In the quote stage of the process, our experts will provide you with a quote we think is required to get the best job done.

Together we can go over any quote concerns, as a well as help conduct any due diligence. We believe in high quality from industry standards after market service.

In the detailed design stage of the process, our experts will blueprint your tailor made fixture we discussed together through the initial stages.

Together we will evaluate and optimize the detail design. Focusing on functionality, operability, safety, as well as durability are the details we find paramount in any design process.

In the review stage of the process, we deep dive into the design to make sure your firm is happy with the design’s functionality and productivity.

Together we will evaluate and optimize the detail design to ensure your tailor made fixture is exactly as you want it to be.

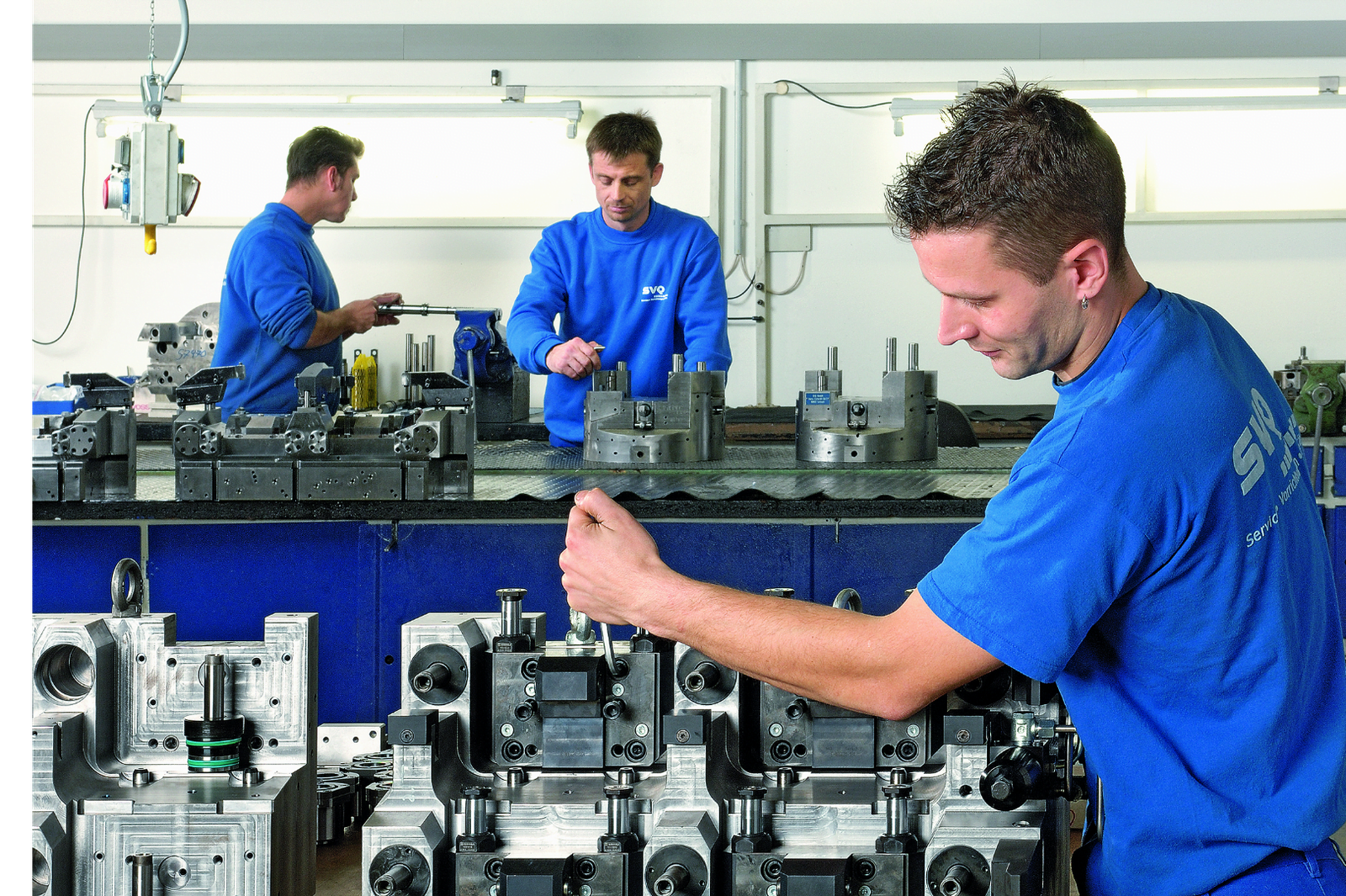

In the production stage of the process, our experts will start crafting your tailored fixture. During this process, you will receive updates on how your piece is developing.

Together we will also go over machine operation procedure, machine know-how, management expertise, as well as quality control systems.

In the assembly stage of the process, we follow the standard operating procedures of our German counterparts in order to complete above standard quality control.

We will evaluate and conduct functionality assessments on your fixture to ensure maximum efficiency and effectiveness.

In the installation and optimization stage of the process, our experts will assist your team in installing and running your tailor made fixture.

Together we will evaluate and optimize your new feature to ensure 100% satisfaction. Our highly experienced service teams will be on stand-by 24/7 to make working with us as seamless as possible.

We will evaluate and conduct functionality assessments on your fixture to ensure maximum efficiency and effectiveness.